Center Spotlight: Saurabh Mhatre

Among the Harvard community – or what he calls Harvard’s research “ecosystem” – Saurabh Mhatre is an accomplished collaborator, translating his architectural research into applications in design, engineering, and medicine.

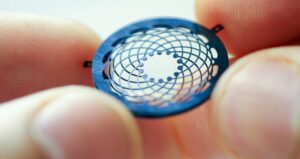

Mhatre, Senior Research Associate at the Material Processes and Systems Group (MaP+S) and Center for Green Buildings and Cities (CGBC) at the Harvard Graduate School of Design (GSD), has most recently been in collaboration with researchers at Kiel University, Germany, where they are exploring how to scale down his patented invention – a novel deployable mechanism ‘Kiriform’ (patent pending) – to use as a medical stent for brain aneurysms.

“I am lucky to be in a full-time research role. It allows me to conduct research and figure out how that knowledge can be disseminated beyond our academic bubble,” said Mhatre, who has been at the GSD for almost 10 years, first as a master’s student and now as a Senior Research Associate. “With one foot in the sciences and one foot in design, I find myself to be in a unique position where I can navigate both fields, delving into the science of something while also making it look beautiful.”

Mhatre’s research combines aesthetics with analytical thinking, which often involves researching emerging materials, processes, and systems in architecture and design, and spending time in the fabrication lab testing out new models and methods of making and fabrication. One of Mhatre’s translational accomplishments includes leading the design and prototyping of a patient isolation hood (medical barrier) to combat COVID-19, in collaboration with Mass General Brigham, Boston Children’s Hospital, and industry partners from Massachusetts.

“Research is not always linear. It requires patience and perseverance, and it is important to be a part of a research ecosystem and community,” said Mhatre. “I think the most rewarding part of research is translation. How can we explain and disseminate the research we do in a language that can be understood by the masses? How can research be more than a publication in a journal?”

Mhatre grew up in Mumbai, India as an aspiring computer engineer, but was surrounded by a family of architects. When it came down to choosing his undergraduate degree, Mhatre decided to shift towards architecture. He has been in the field ever since.

“I have always been extremely curious about how things work and how they are built. When I was young, I would disassemble my toys to understand them. I still have this curiosity,” said Mhatre.

Mhatre’s interests in design, technology, and materials also overlap with many of his hobbies, which include creating physical and digital art, photography and drone photography, listening to electronic music, spending time outdoors, and kayaking on the Charles River.

Above all, Mhatre believes in the translation of his work and in interdisciplinary collaboration. He feels strongly that his unique position at the GSD has allowed him to make huge advancements and propel his work in extraordinary ways. Importantly, he recognizes how his work in materials science intersects with issues of sustainability.

“Sustainability is a systemic goal and hence is a very complex problem. Creative solutions to complex problems are possible only when you work with people across fields towards a common goal,” said Mhatre. “Materials play a very important role in determining how our spaces behave. For example, how can we design materials to perform in particular ways?”

Mhatre’s work also involves the use of industrial robotic arms for the multi-material 3D printing of ceramics. This offers a novel approach to sustainable manufacturing, as it reduces material waste and energy consumption while enabling the creation of complex shapes and designs.

Whether he is testing new models in the fabrication lab, researching new materials, or kayaking on the Charles River, Mhatre goes through life appreciating materials and physicality. With materials, Mhatre is sure to create something both scientific and beautiful.

Saurabh Mhatre has published many research papers, including, “3D Printing of Hierarchical Porous Ceramics for Thermal Insulation and Evaporative Cooling,” “Surface texture modulation via buckling in porous inclined mechanical metamaterials,” and “Post-tensioned ceramic structures: design, analysis and prototyping,” which can be viewed under our Publications page.